V PULLEY

Processing customization

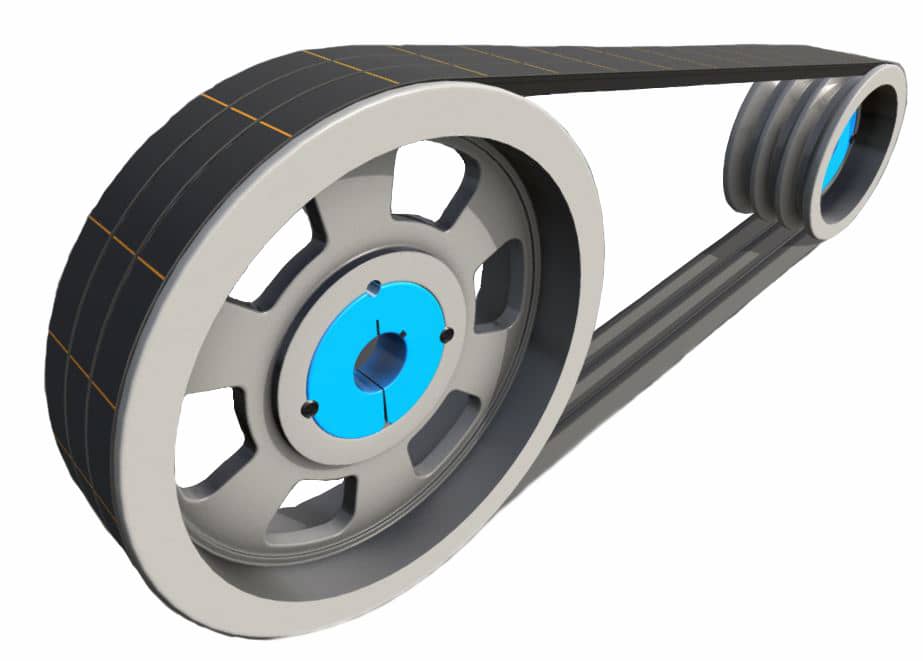

V-belt pulleys (also called vee belt sheaves) are devices which transmit power between axles by the use of a v-belt, a mechanical linkage with a trapezoidal cross-section. Together these devices offer a high-speed power transmission solution that is resistant to slipping and misalignment.

V-Belt Pulleys

V-belt pulleys are used with a compatible V-belt to transmit mechanical rotating power to a shaft. The V-shaped grooves in a V-belt pulley prevent slippage and misalignment and provide maximum friction and torque in a drive system. They are found in many rotating mechanical power applications such as fans, pumps, air compressors, and conveyors.

V-belt pulley

Cast iron V-belt pulley, V-belt pulley, V-belt pulley, V-groove pulley, tapered locking pulley, variable speed V-belt pulley.

The V-groove pulley is an indispensable transmission part for mechanical operations. Different mechanical equipment has V-groove pulleys of different specifications and sizes, especially large V-groove pulleys for large machinery are more expensive, so pay attention to maintenance. V-groove pulleys are suitable for high power and transmissions that require a compact transmission mechanism. V-groove pulleys are mainly used for long-distance transmission of power, such as small diesel engine power output, agricultural vehicles, tractors, automobiles, mining machinery, machining equipment, textile machinery, packaging machinery, lathes, forging machinery, some small horsepower motorcycles and automobiles Power transmission, agricultural machinery power transmission, air compressor, reducer, generator, cotton gin, etc.

A pulley, also known as a sheave, is a mechanism consisting of a wheel or shaft that may have a groove between two flanges around the circumference of the wheel or shaft. If present, a belt or chain usually runs over the wheels and in grooves.

Pulleys are used to change the direction of applied force, to transmit rotational motion, or to achieve mechanical advantage in linear or rotary motion systems. It is one of six simple machines. Two or more pulleys together are called a pulley block.

Technically qualified product for V-belt drive pulleys for all types of equipment and machinery. Your full specification will provide us with a more specific supply of the required pulleys. We also produce customized products according to customers’ sizes and special requirements. V-belt pulleys are available.

Features

- Easy to install or replace.

- Available in solid, web, spoke, rib

- 2″ to 36″ casters available

- Batch size can be customized according to drawings. Continuous supply.

- The belt part in the pulley can be used for A, B, C, SPA, SPB, SPC

- Number of Slots Single and Multiple Slots

- durable

- maintenance free

- proper power transmission

V-Belt Pulley Specifications

The following parameters are important when selecting v-belt pulleys.

Belt profile, or the style and sizes of the belt being integrated.

Outside diameter, or the distance across the pulley when measured between groove edges.

Center diameter is the distance or distances between the shafts of the pulleys in the transmission. V-belt transmissions are limited by center distances, which must be no more than three-times the diameter of the largest pulley, lest significant slipping can occur.

Grooves, the grooves located on the pulley, including the number, and angle and width of the flanges.

Pitch diameter, or the diameter of the pulley where the belt is engaged, and is critical to the drives strength-to-weight ratio.

Arc of contact, the degree of which the belt wraps around the pulley.

Spur Gear

1. Produce strictly in accordance with ANSI or DIN standard dimension

2. Material: SCM 415 steel

3. Bore: Finished bore

4. Precision grade: DIN 5

5. Surface treatment: Carburizing and Quenching

6. Module: From 1 to 4

7. Tooth: From Z15 to Z70

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | External Gear |

| Manufacturing Method: | Rolling Gear |

| Toothed Portion Shape: | Spur Gear |

| Material: | Stainless Steel |

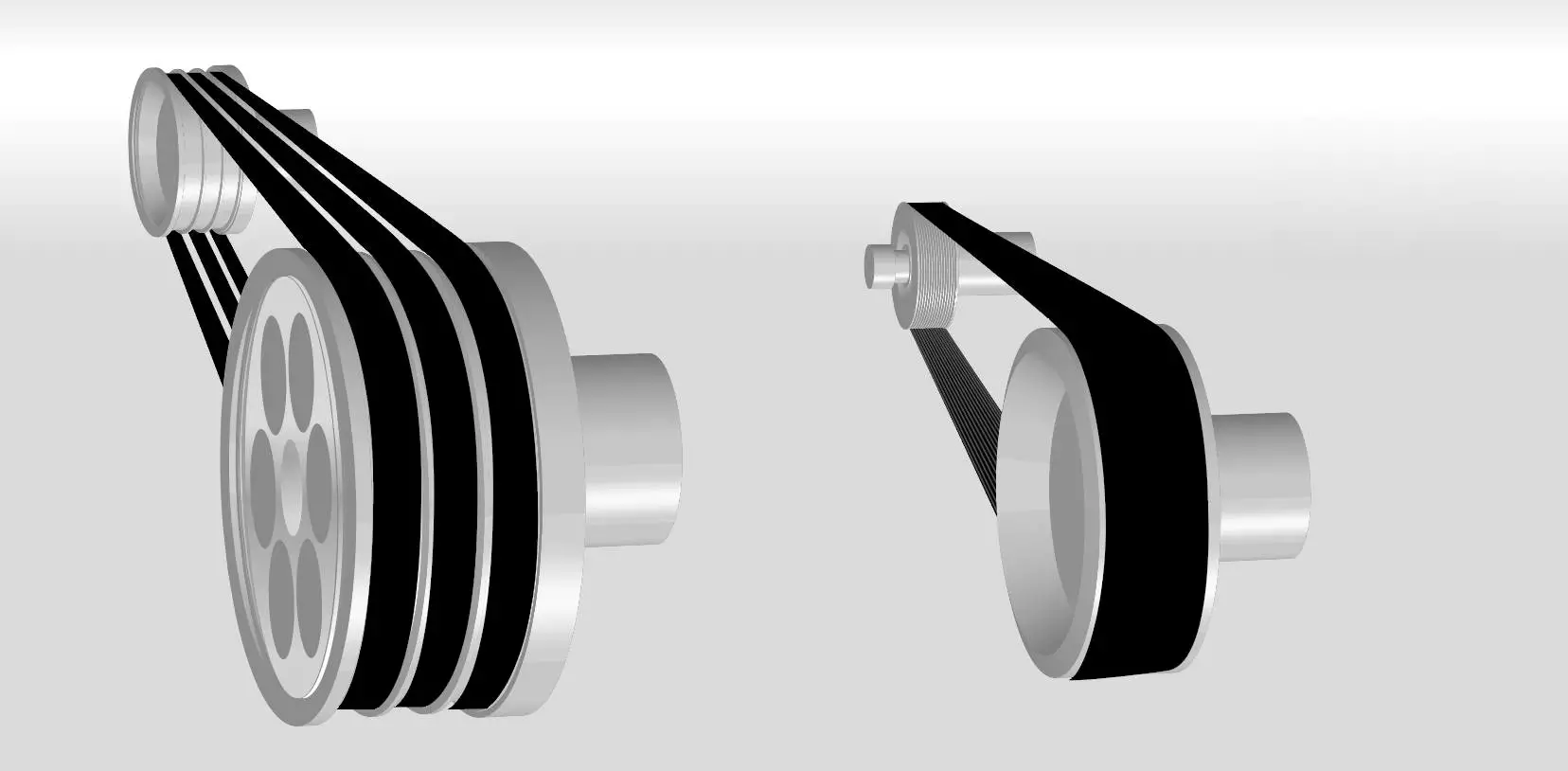

Also known as: Step Pulleys, Multi Groove Pulleys, Multi V-Pulleys, Multi V-Belt Pulleys, Cone Pulleys, Stepped Cone Pulleys.

Stepped pulleys provide a low cost and efficient means of enabling a selection of speeds. Speed changes are made when the drive is stationary, the belt tension must first be released and the belt manually relocated in an alternative set of grooves.

In many arrangements the pulley centre distance remains virtually unchanged. Stepped pulleys are produced from a one piece aluminium casting and are machined with groove profiles to accept standard V-Belts. Where the diameters allow wedge belts may also be used.

Specificaton:Standard or Custom made

Material: Stainless steel$comma;,brasss,carbon steel,aluminum,and so on &period

Surface Treatment:

Zn-plating, Ni-plating, Cr-plating, Tin-plating, Copper-plating, the wreath oxygen resin spraying, black oxide coating, painting, powdering, color zinc-plated,blue black zinc-plated, silver plating,anodizing etc.

Management System:IOS9001-2008

WHY CHOOSE US?

Production process

Our company has long-term storage of hundreds of thousands of models of each series,which can quickly meet the special needs of customers and provide customers with services such as type aelection design and technical consultation

Holding advanced production processing equipment,on-site maintenance,on-site shuttle service.At the same time,we can be used according to customer’s special demand,professional processing of all konds of special belt

Our products are well known in the local market in China as well as in the global markets, such as European and North American countries. In addition, we are the sole authorised distributor in the Greater China Area for many world-renowned high-tech industrial products from Germany, Switzerland, Italy, USA, Japan and Taiwan. These products can be applied to railway, aerospace, marine, chemistry, food/beverage, environmental production and machinery industries, etc.